Content

The Verdict: Superior for High Stress, But Not Universal

To answer the question directly: Yes, T-bolt hose clamps are significantly better for high-pressure, high-vibration, and large-diameter applications compared to standard worm gear clamps. However, they are not the "better" choice for every scenario.

T-bolt clamps are engineered to provide a uniform, positive seal without cutting into the hose. They are the industry standard for turbocharged forced induction systems, industrial machinery, and heavy-duty coolant lines. If you are dealing with pressures exceeding 30 PSI or silicone couplers that are prone to popping off, a T-bolt clamp is the superior upgrade. Conversely, for small fuel lines or household plumbing with low pressure, they are often overkill and less effective due to their limited adjustability.

Why T-Bolt Clamps Offer Superior Sealing

The primary reason T-bolt clamps outperform standard options lies in their mechanical design. Unlike worm gear clamps, which rely on threads cutting into a slotted band, T-bolt clamps use a solid metal band pulled tight by a heavy-duty T-bolt and nut.

360-Degree Contact

Standard clamps often create a "flat spot" under the screw mechanism, which is a common leak point. T-bolt clamps often feature a floating bridge design that ensures the clamp remains perfectly round as it tightens. This results in 360-degree even pressure distribution, which is critical for preventing leaks in systems carrying air or fluids under load.

Protection of Soft Hoses

Because the band of a T-bolt clamp is typically wider (often 19mm or 0.75 inches) and smooth (no gear slots), it does not chew into the hose material. This makes them safest for expensive silicone hoses used in automotive intercoolers or radiator systems, preventing the rubber from extruding through the band slots.

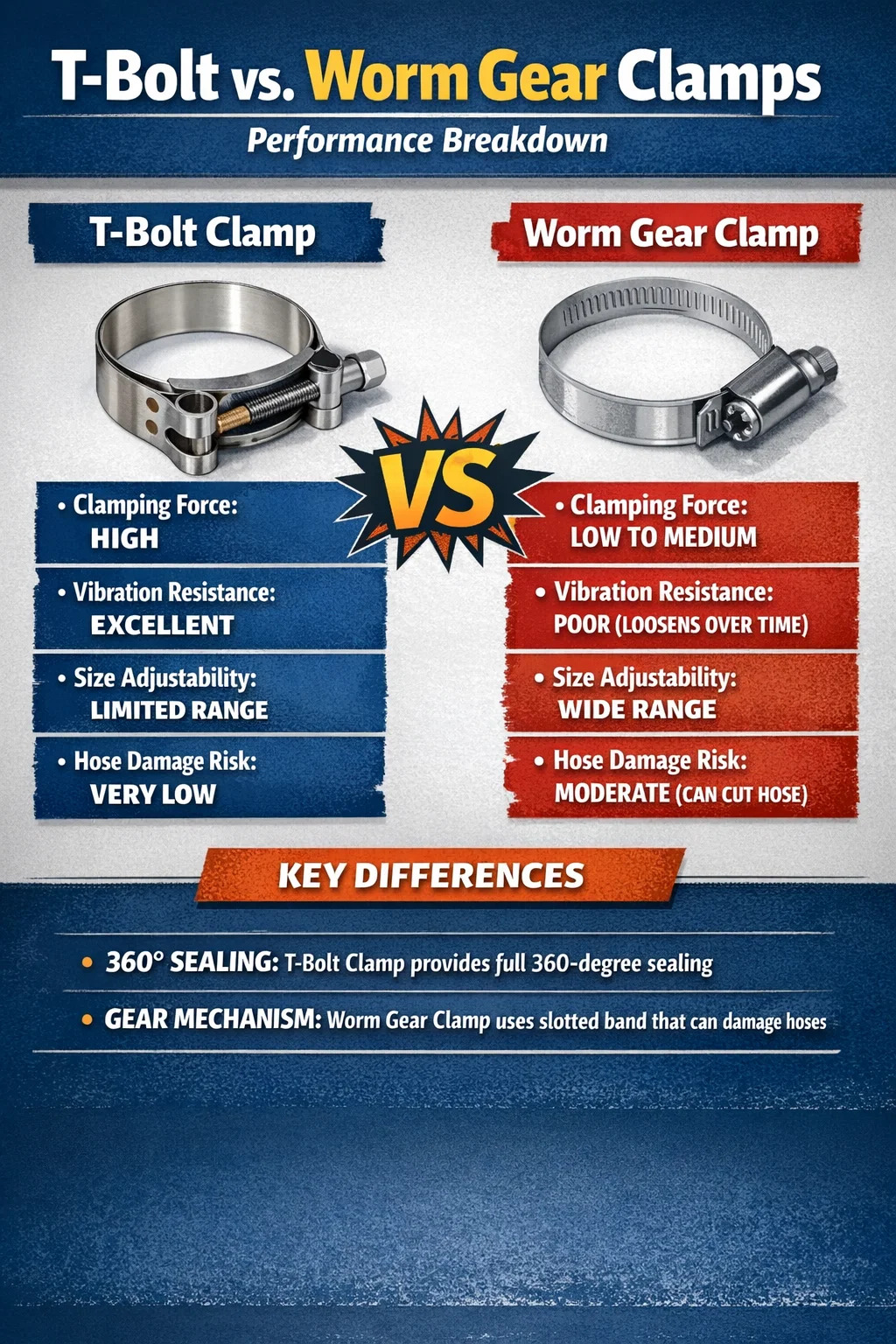

Comparison: T-Bolt vs. Worm Gear Clamps

Understanding the technical differences helps determine which clamp is "better" for your specific project.

| Feature | T-Bolt Clamp | Worm Gear Clamp |

|---|---|---|

| Clamping Force | High | Low to Medium |

| Vibration Resistance | Excellent | Poor (Loosens over time) |

| Size Adjustability | Very Limited (approx. 1/16") | Wide Range |

| Hose Damage Risk | Very Low | Moderate (Can cut hose) |

The Main Downside: Critical Sizing Requirements

While T-bolt clamps are better performers, they are significantly harder to buy if you do not have exact measurements. A standard worm gear clamp might cover a range of 1 inch to 2 inches, allowing for plenty of error.

In contrast, a T-bolt clamp typically has an adjustment range of only 1.5mm to 3mm. If your hose Outer Diameter (OD) is 55mm and you buy a clamp designed for 58mm-62mm, it simply will not tighten enough to seal. To use T-bolt clamps effectively, you must:

- Measure the outside diameter of the hose while it is installed on the pipe.

- Account for the expansion of the hose when the fitting is inserted.

- Select a clamp where your measurement falls in the middle of the clamp's operational range.

Ideal Applications for T-Bolt Clamps

To determine if switching to T-bolt clamps is the right move for your project, consider if you fall into one of these categories where they are the undisputed "better" choice:

- Turbocharger & Intercooler Piping: The most common use case. When boost pressure hits 20+ PSI, worm gears often fail. T-bolts handle the expansion and pressure spikes without slipping.

- Industrial Water Pumps: For thick-walled suction and discharge hoses where vibration from the pump motor would cause standard screws to back out.

- Heavy Duty Exhaust Systems: Stainless steel T-bolt clamps are frequently used to secure exhaust tips or muffler connections where welding isn't an option.

英语

英语 俄语

俄语