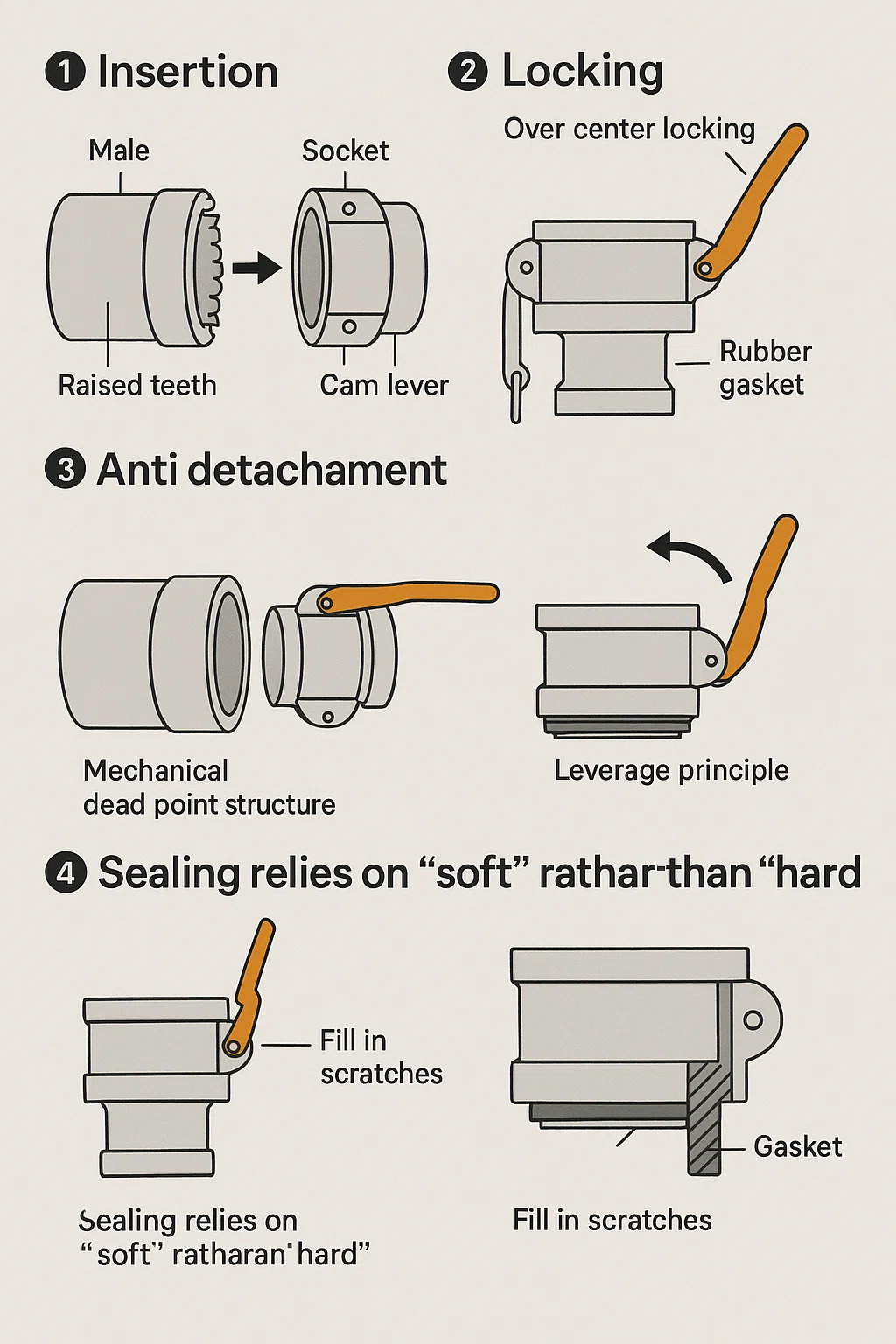

Here's of how camlock fittings work :

1. Insertion: Male and female heads fiercely confront each other

Plug: The front end has raised teeth and rubber ring grooves, resembling a beer bottle lid.

Socket: L-shaped card slot and cam lever on the inner wall, like a trap.

Operation: Insert the male head into the female head, and slide the locking teeth into the bottom of the L groove - do not align with the thread, kick it in if it is crooked.

2. Locking: The cam eats the dead center and the wheel eats the dead center

Cam lever downward pressure: Rotate the handle to drive the eccentric cam, which clicks into the male tooth root like a switch.

Over center locking: Over center locking * *: The cam locks itself after turning the critical point, and the tighter it is pulled (similar to the "click" sound of a luggage buckle).

Rubber gasket flattening: The downward pressure of the cam squeezes the gasket into a "meat pie", and the gasket squeezes into a "meat pie", filling the metal surface defects to achieve sealing.

3. Anti detachment: The more intense the vibration, the stronger the lock

Mechanical dead point structure: The cam is stuck in the male tooth groove, and vibration actually makes the bite more rigid.

Practical experience of oil tanker: When the road is bumpy, the flange joint bolts may loosen, and the cam joint may shake overnight without moving.

4. Unlock: Kick open to save life

Leverage principle: Lift the cam handle and use the fulcrum to pry open the locking teeth.

Emergency disconnection: When the hose bursts, the worker kicks the handle and instantly disconnects (10 seconds faster than finding a wrench).

5. Sealing relies on "soft" rather than "hard"

Relying on 'hard'

Rubber crushing everything: After the gasket is deformed by compression: ▶ Fill in metal scratches ▶ Wrap around sand particles/dirt ▶ Seal the slightly deformed surface

The metal surface can be rough: it doesn't matter if the lathe blade is deeper, the rubber is soft enough to seal the leak.

英语

英语 俄语

俄语