Here's how hose clamps actually work in plain terms:

Content

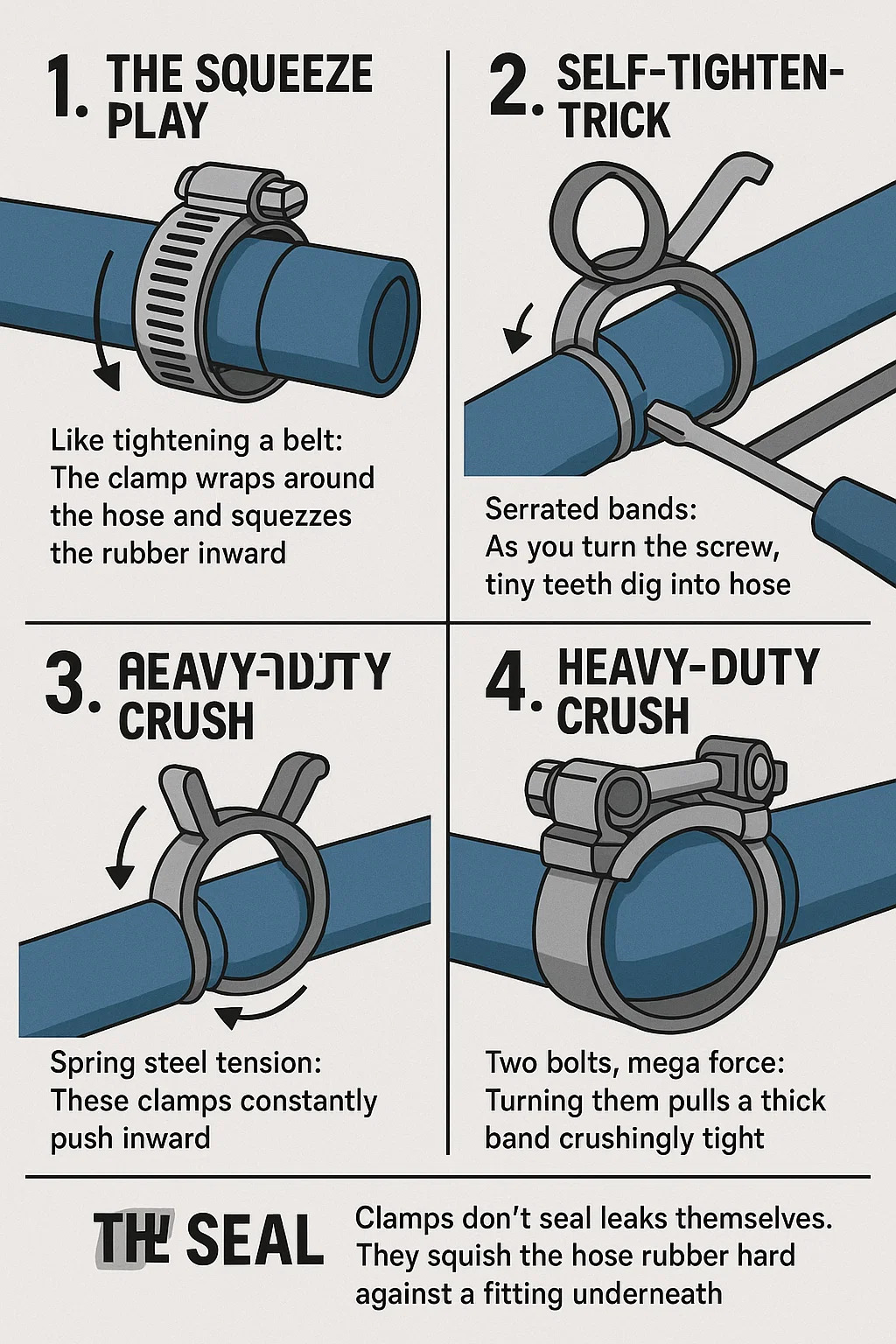

1. The Squeeze Play

Like tightening a belt: The clamp wraps around the hose where it meets a pipe fitting (like a barbed nipple). When you tighten it, the clamp squeezes the hose rubber inward.

Why it works: This compression makes the rubber grip the fitting underneath way tighter than your hands ever could.

2. The "Bite"

Serrated bands (Worm Gear Clamps):

The clamp band has tiny teeth. As you turn the screw, these teeth dig gently into the hose surface – not enough to cut, just enough to lock it in place.

Think: A zip-tie that grips tighter as you pull the tab.

3. Self-Tightening Trick (Spring Clamps)

Spring steel tension: These clamps look like a ring with two tabs. You squeeze the tabs to open them, slide them on, and let go.

Why they don't slip: The spring steel constantly pushes inward, like a rubber band pulling tight. If the hose shrinks (cold) or swells (heat), the clamp adjusts automatically.

4. Heavy-Duty Crush (T-Bolt Clamps)

Two bolts, mega force: Used for high-pressure hoses (like turbochargers). Turning the bolts pulls a thick band crushingly tight.

Visual check: When properly tightened, you'll see the hose rubber bulge slightly on either side of the clamp.

5. The Seal

Clamps don't seal leaks themselves. They work by squishing the hose rubber so hard against the fitting underneath that fluids can't find a path to escape. If the fitting is scratched or the hose is cracked, even a tight clamp won't help.

英语

英语 俄语

俄语