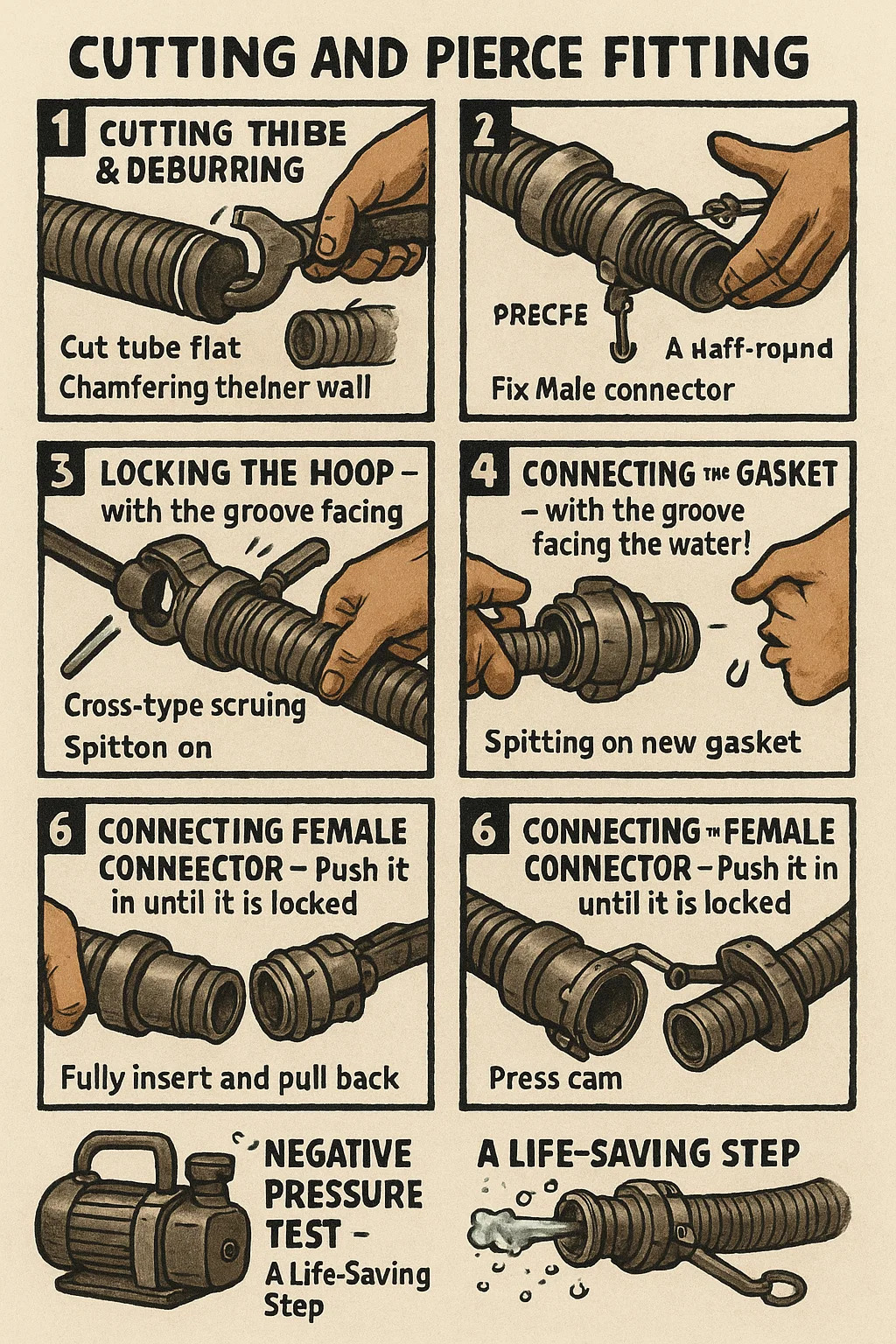

Here's a gritty, step-by-step guide from the field for installing a camlock fitting on a suction hose:

1. Cutting the Tube & Deburring

Cut the Tube Flat: Use a pipe cutter to cut the suction hose end flush. Avoid sawing (serrations can leak air).

Chamfering the Inner Wall: Use a half-round file to smooth the plastic edges inside the tube to prevent particles from being sucked in and blocking the pump.

2. Sleeve and Pierce Fitting

Reverse the Hoop: Thread the metal ferrule (screw-side) upside down about 1 cm against the inside of the inlet pipe. Lubricate it with soapy water. ▶ Tip: Use a screwdriver to pry open the pipe opening and force it in; don't worry about it cracking.

Fix the Male Connector: Wrap the camlock connector (a toothed rod) with Teflon tape and insert it into the pipe, pressing against the ferrule. Leave at least 5 mm of exposed teeth.

3. Locking the Hoop – Tighten it as hard as you can!

Cross-type screwing: Tighten the ferrule bolts in a diagonal sequence (e.g., No. 1 → No. 3 → No. 2 → No. 4).

Tighten with the wrench until a deep groove is pressed into the rubber hose and the edge of the ferrule sinks into the hose. ▶ Warning: Use iron ferrules for aluminum fittings and stainless steel ferrules for stainless steel fittings—mixing these can cause electrochemical corrosion.

4. Installing the gasket – with the groove facing the water!

Cleaning the groove of the old gasket: Use your fingernail to remove any rust or old glue from the sealing groove of the fitting. Do not scrape with a knife (this may damage the groove and cause air leakage).

Spitting on the new gasket: Moisten the fluororubber gasket with saliva and press the concave surface (with the lip) into the groove facing the direction of the water flow. ▶ Don't: Never apply grease to the gasket (negative pressure will draw air in and cause cavitation).

5. Connecting the female connector – Push it in until it is locked.

Fully insert and pull back: Push the female connector into the male connector until it stops, then pull back 2mm (to create space for the gasket). Press the cam to lock: Press the handle past the critical point (you'll hear a "click"), then push it again to ensure it's locked.

6. Negative Pressure Test – A Life-Saving Step

Check for leaks with soapy water: Turn on the vacuum pump and apply strong soapy water to the connector. If bubbles form, it's a leak.

Test the suction by blocking the nozzle: Block the nozzle with your hand. If the vacuum gauge remains stable for 5 seconds, it's a pass.

英语

英语 俄语

俄语