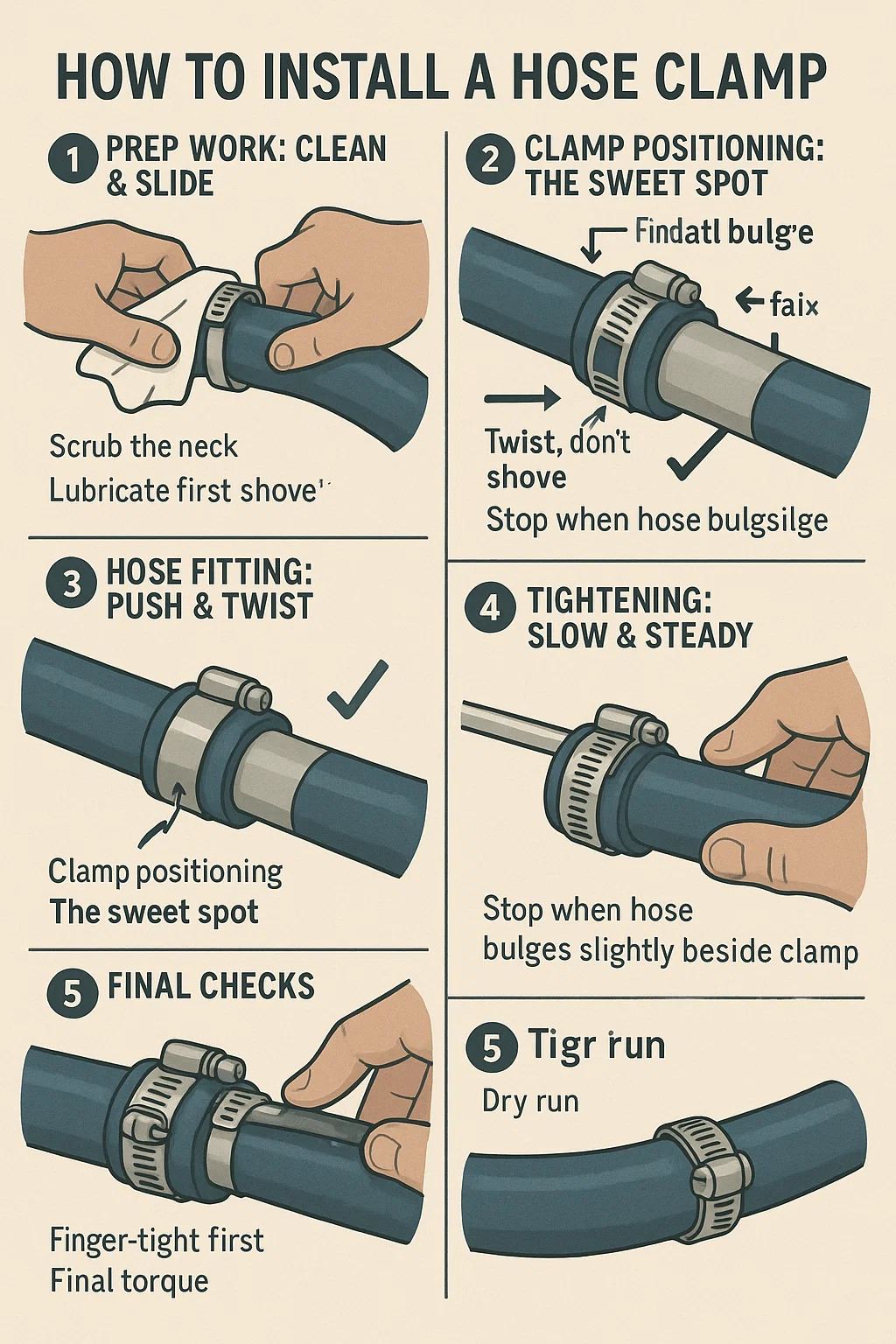

Here's how to install a hose clamp correctly:

Content

1. Prep Work: Clean & Slide

Scrub the neck: Wipe the pipe fitting (where the hose attaches) with a rag. Dirt or old gasket scraps cause leaks.

Slide the clamp on FIRST: Always slip the clamp onto the hose before pushing the hose onto the fitting. Forgetting this means disassembling everything!

2. Hose Fitting: Push & Twist

Lubricate if stubborn: For tight hoses, dab soapy water or silicone spray on the pipe fitting. Never use oil – it rots rubber.

Twist, don't shove: Rotate the hose back and forth while pushing. You'll feel a solid "thunk" when it seats fully against the fitting's ridge.

3. Clamp Positioning: The Sweet Spot

Find the bulge: Look/feel for the raised shoulder on the fitting. Position the clamp so it covers this ridge completely.

Too far forward: Cuts hose.

Too far back: Hose slips off.

Align screws: Point the clamp's adjustment screw where you can reach it easily later.

4. Tightening: Slow & Steady

Finger-tight first: Turn the screw/driver until resistance starts.

Final torque:

Worm gear clamp: Tighten ¼ turn with a screwdriver.

T-bolt clamp: Snug nuts crosswise (like lug nuts) until gap closes.

Spring clamp: Use pliers to squeeze tabs until parallel.

Stop when: Hose bulges slightly beside the clamp. More = crushing!

5. Final Checks

Tug test: Gently pull the hose. No movement? Good.

Dry run: Run fluid without pressure (e.g., fill a coolant system). Check for drips.

Re-tighten if needed: Some hoses settle after heat cycles. Check clamps after first use.

英语

英语 俄语

俄语