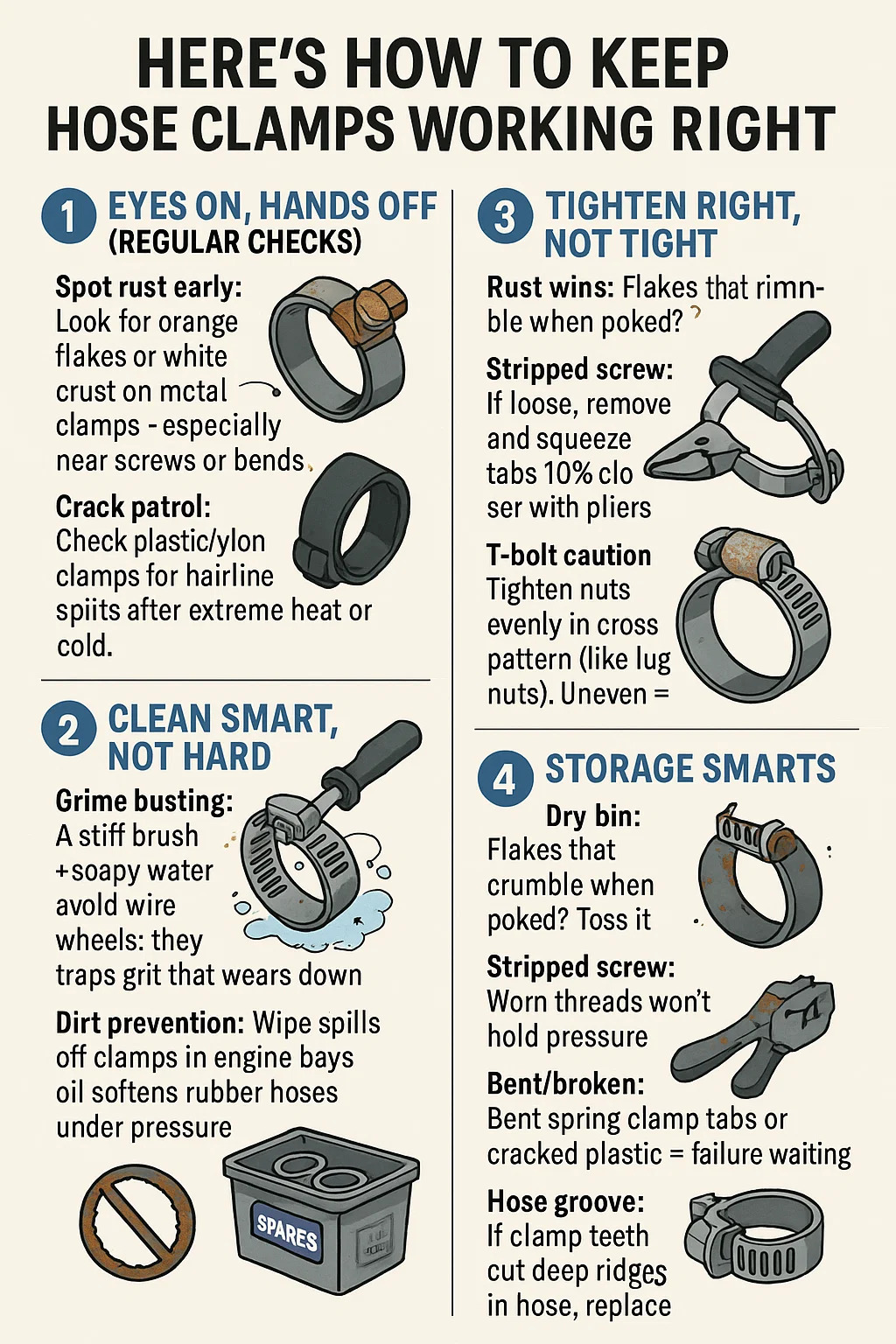

Here's how to keep hose clamps working right:

Content

1. Eyes On, Hands Off (Regular Checks)

Spot rust early: Look for orange flakes or white crust on metal clamps – especially near screws or bends.

Crack patrol: Check plastic/nylon clamps for hairline splits after extreme heat or cold.

Tension tells: Spring clamps with a visible gap between ends? Tension's gone – replace it.

2. Clean Smart, Not Hard

Grime busting: Scrub grimy clamps with a stiff brush + soapy water. Avoid wire wheels – they eat protective coatings.

No oil/grease: Never lube worm gear threads – it traps grit that wears down teeth.

Dirt prevention: Wipe spills off clamps in engine bays – oil softens rubber hoses under pressure.

3. Tighten Right, Not Tight

Worm gear rule: Finger-tighten screw, then ¼ turn with screwdriver – stops leaks without crushing hoses.

Spring clamp reset: If loose, remove and squeeze tabs 10% closer with pliers – but don't over-bend!

T-bolt caution: Tighten nuts evenly in cross pattern (like lug nuts). Uneven = leaks.

4. Replace When

Rust wins: Flakes that crumble when poked? Toss it.

Stripped screw: Worn threads won't hold pressure.

Bent/broken: Bent spring clamp tabs or cracked plastic = failure waiting.

Hose groove: If clamp teeth cut deep ridges in the hose, replace both.

5. Storage Smarts

Dry bin: Keep spares in a sealed container with silica gel packs to fight rust.

Size sort: Label bins by clamp diameter – no fumbling during repairs.

No sunbaking: UV rays weaken plastic clamps – store indoors.

英语

英语 俄语

俄语