Here's a practical breakdown of hose clamp sizing for real-world use:

Content

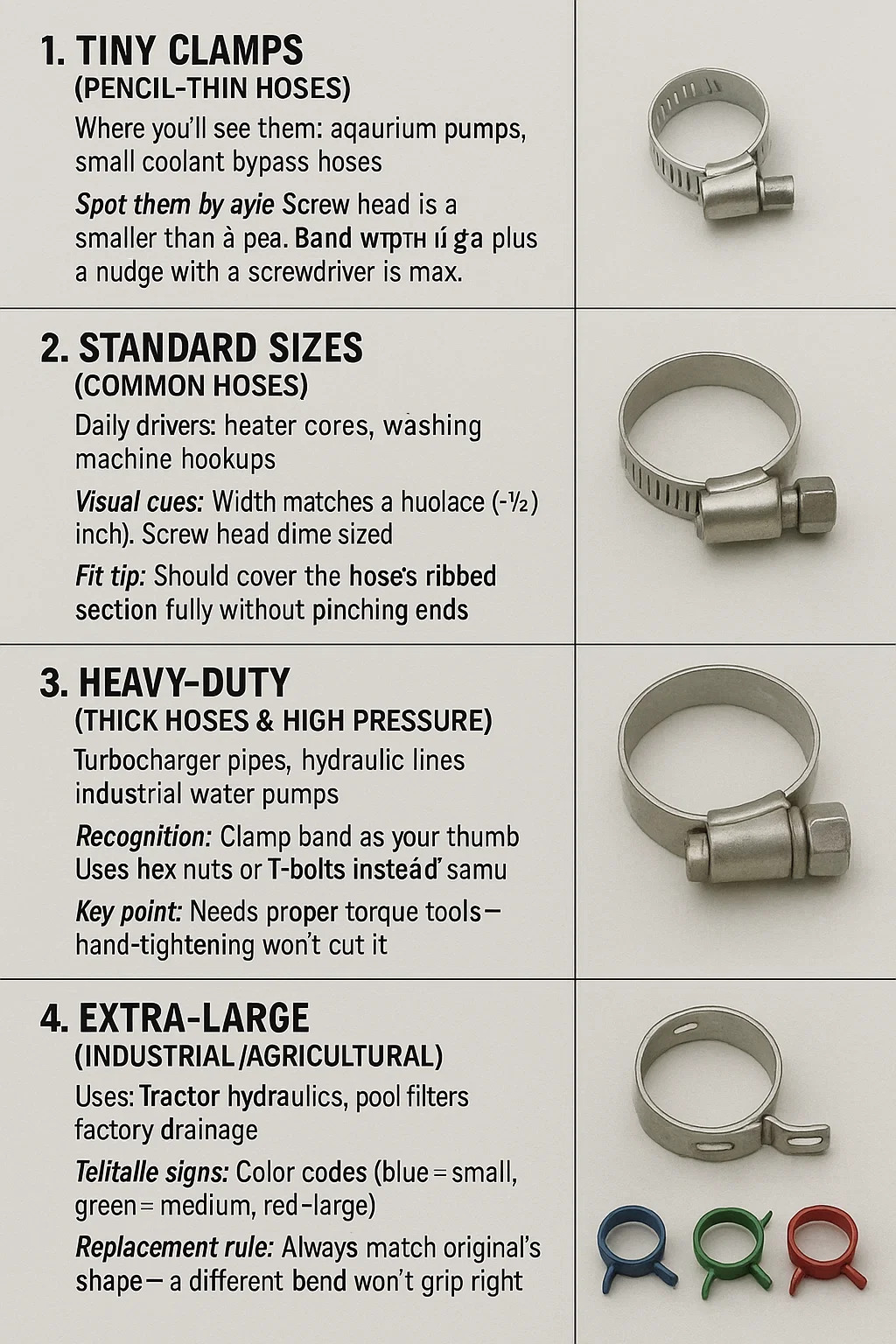

1. Tiny Clamps (Pencil-Thin Hoses)

Where you'll see them: Fuel injector lines, aquarium pumps, small coolant bypass hoses.

Spot them by eye: Screw head is smaller than a pea, band width like a toothpick.

Warning: Overtightening snaps these instantly. Finger-tight plus a nudge with a screwdriver is max.

2. Standard Sizes (Common Hoses)

Daily drivers: Radiator hoses, heater cores, washing machine hookups.

Visual cues:

Width matches a shoelace (~1/2 inch).

Screw head is dime-sized.

Fit tip: Should cover the hose's ribbed section fully without pinching ends.

3. Heavy-Duty (Thick Hoses & High Pressure)

Typical jobs: Turbocharger pipes, hydraulic lines, industrial water pumps.

Recognition:

Band as wide as your thumb.

Uses hex nuts or T-bolts instead of small screws.

Key point: Needs proper torque tools – hand-tightening won't cut it.

4. Extra-Large (Industrial/Agricultural)

Uses: Tractor hydraulics, pool filters, factory drainage.

Telltale signs:

Clamp band resembles a fender washer.

Requires two wrenches to tighten.

Field hack: For odd sizes, pros overlap two clamps side-by-side.

5. Spring Clamp Sizes (No Adjustments)

Found in: Car engine bays (factory coolant hoses), appliances.

Sizing secret: Color codes (blue=small, green=medium, red=large).

Replacement rule: Always match the original's shape – a different bend won't grip right.

英语

英语 俄语

俄语