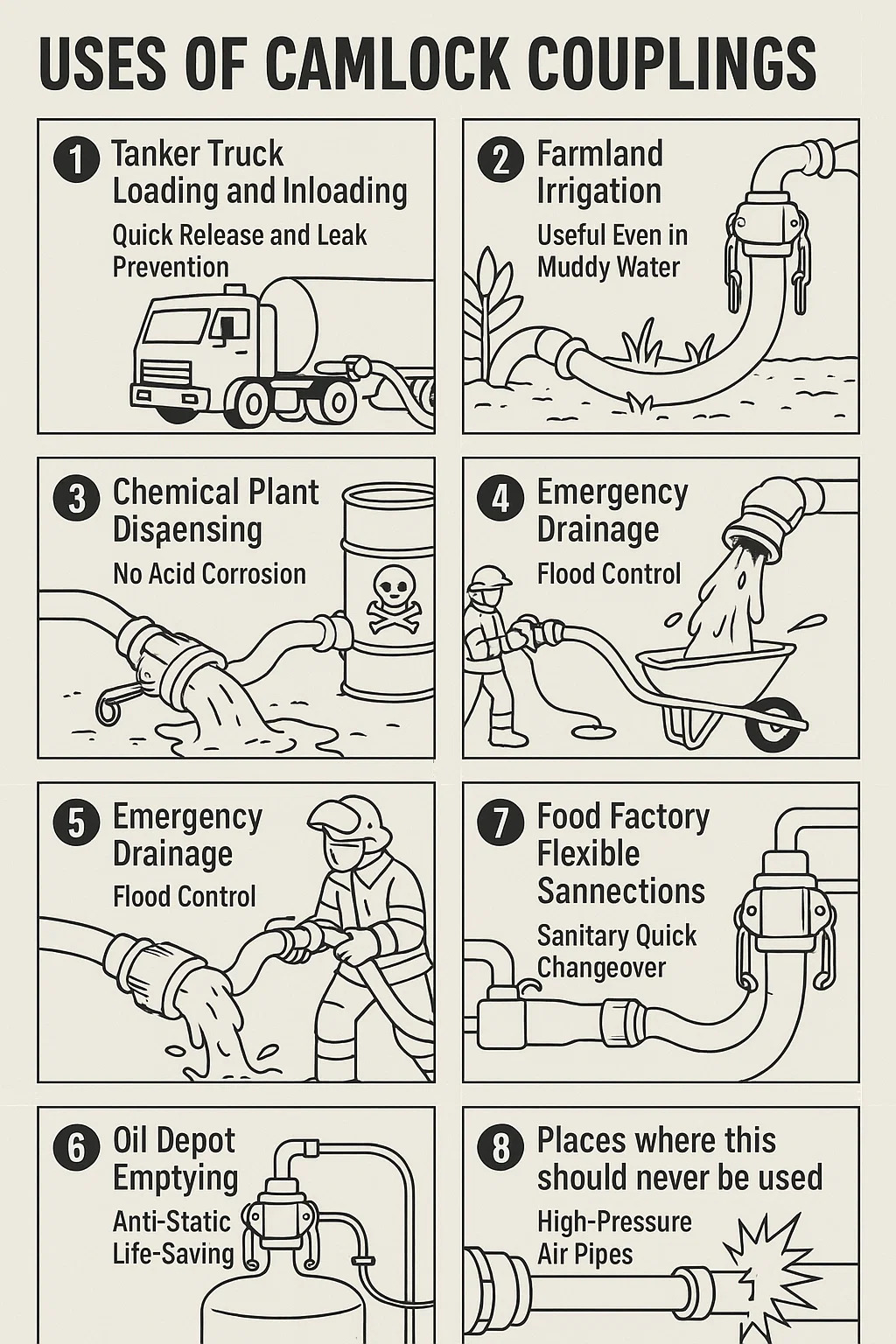

Here's a straight-talking breakdown of what camlock couplings are actually used for, on the ground:

1. Tanker Truck Loading and Unloading

Quick Release and Leak Prevention: When unloading gasoline/diesel, the cam locks in place for 3 seconds with a single press, and the rubber gasket seals the fuel, preventing it from leaking.

No Loosening Affected by Bumps: The cam tightens with vibrations on bumpy dirt roads, even before the bolt flanges loosen.

2. Farmland Irrigation

Useful Even in Muddy Water: Just plug in a mud-covered hose and water will flow. Threaded joints must be cleaned first.

Blind Connections for Ease: Can't See Clearly in the Dark? Simply feel the cam handle and flip it, locking the connection. Farmers can operate with one hand.

3. Chemical Plant Dispensing

No Acid Corrosion: Replace the fluororubber gasket to withstand hydrochloric acid/caustic soda. If it leaks, just kick the handle and it will disconnect instantly.

No Odor Transfer in Mixed Materials: Use specialized gaskets (nitrile rubber/PTFE) for different solvents, saving time compared to cleaning pipes.

4. Mortar Transport on Construction Sites

Wear and Durability: Will the mortar wear out the aluminum joints? It's fine; the gasket flattens and traps the sand, sealing the gap as normal.

Forced repair: Is dried cement stuck? Hit the cam twice with a sledgehammer, pry it open, and continue using.

5. Emergency drainage

Flood control: Firefighters pump out floodwaters in a hurry. Cams are 10 times faster than flanges, removing half a truckload of water.

Dirty water doesn't get blocked: Branches and sludge get into the joints? Just run over them with a rubber gasket and it'll flow.

6. Oil depot emptying

Anti-static life-saving: Aluminum joints with static jumper cables prevent fires when unloading aviation fuel.

Lightweighting first: Aluminum is 60% lighter than stainless steel, saving effort when working at height.

7. Food factory flexible connections

Sanitary quick changeover: Changing flavors on a yogurt filling line requires removing the cam and flushing it with water for a minute, while stainless steel flanges require half an hour to disassemble and clean.

Qualified gaskets: Food-grade silicone rings come into direct contact with the material and are FDA-approved.

8. Places where this should never be used

High-pressure air pipes: Compressed air stores energy, causing the cam to explode like a cannonball when released. Liquid oxygen delivery: Rubber gaskets become brittle and burst when exposed to ultra-low temperatures.

Ultrapure water systems: Silicon extractables contaminate semiconductor chips.

英语

英语 俄语

俄语