Content

What is a hose clamp?

1. Essence: A "steel-toothed throat clamp" for hoses

Hose are inherently prone to slipping: they bulge and detach under pressure, potentially causing fluid leakage and even bursting.

Clamps do the dirty work:

Throat clamping: The metal blades with serrations cut into the hose, tightening deeper and deeper (using the principle of barbs).

Locking ribs: Screws/springs: The screws/springs forcefully tighten, deforming the hose wall and locking the joint.

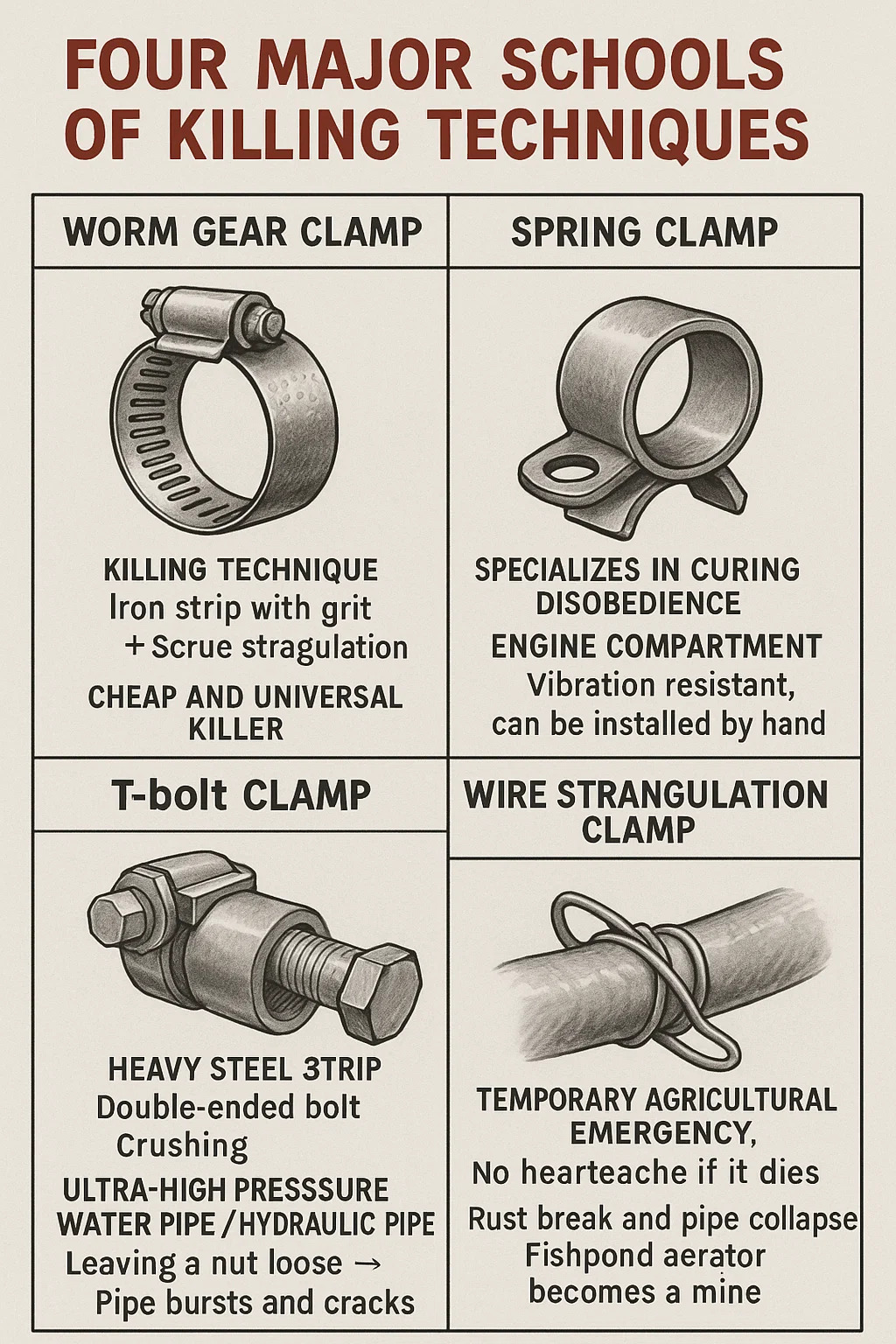

2. Four Major Schools of Killing Techniques

| Type | Killer Move | Where It Reigns | Suicide Move |

|---|---|---|---|

| Worm Gear Clamp | Serrated band + screw vise-grip | Cheap all-rounder | Teeth cut through hose → high-pressure shower |

| Spring Clip | Tempered steel self-squeeze | Engine bay vibrations | Fatigue → slips off → coolant geyser |

| T-Bolt Clamp | Heavy band + twin-bolt crusher | Hydraulic monsters (3000+ PSI) | Miss one nut → hose explodes like grenade |

| Wire Twist | Galvanized wire garrote | Farm ditch fixes | Rusts Farm ditch fixes |

3. Blood and Tears Installation Ironclad Rules

Worm Gear Clamp Positioning: 1mm behind the barbed shoulder of the joint → Moving forward will strangle the pipe, moving backward will cause it to fly off.

Screw head facing outwards! Inwards will trap your hand and expose the bone.

Spring Clamp Taboo:

Do not use pliers to force open the opening → Steel sheet will crack, and it will break after three days. Soaking in engine oil before installation → Rubber hoses swell, leaking more with tighter tightening.

T-bolt torture: Tighten the bolts progressively (1→3→2→4 sequence) → Torque disappears at the flange seam → Stop! Tightening further will break the neck.

4. Material betrayal guide

| Material | Betrayal Trigger | Catastrophic Failure |

|---|---|---|

| 304 Stainless | 3 months in coastal salt fog | Teeth rot to lace → clamping force → ZERO |

| Galvanized Steel | Acid splash (even drops) | Zinc layer eaten through → rust swells → SNAPS |

| Thermoplastic Nylon | Under-hood heat soak | Softens to noodles → hose slips →oodles** → hose slips → oil line suicides |

5. Three deadly forbidden zones

Heat pipes with spring clamps:

Exhaust pipe temperature → Spring annealing → Idle speed is like being scalded by boiling water.

Saving bolts on hydraulic pipes:

Leaving one T-bolt loose → 300 bar hydraulic pressure cuts steel bars like tofu.

Using iron clamps with acid pipes:

Hydrogen acid seepage:

Hydrogen acid seeps into gaps → Rust expansion cracks the pipe → Acid dripping corrodes shoes.

英语

英语 俄语

俄语