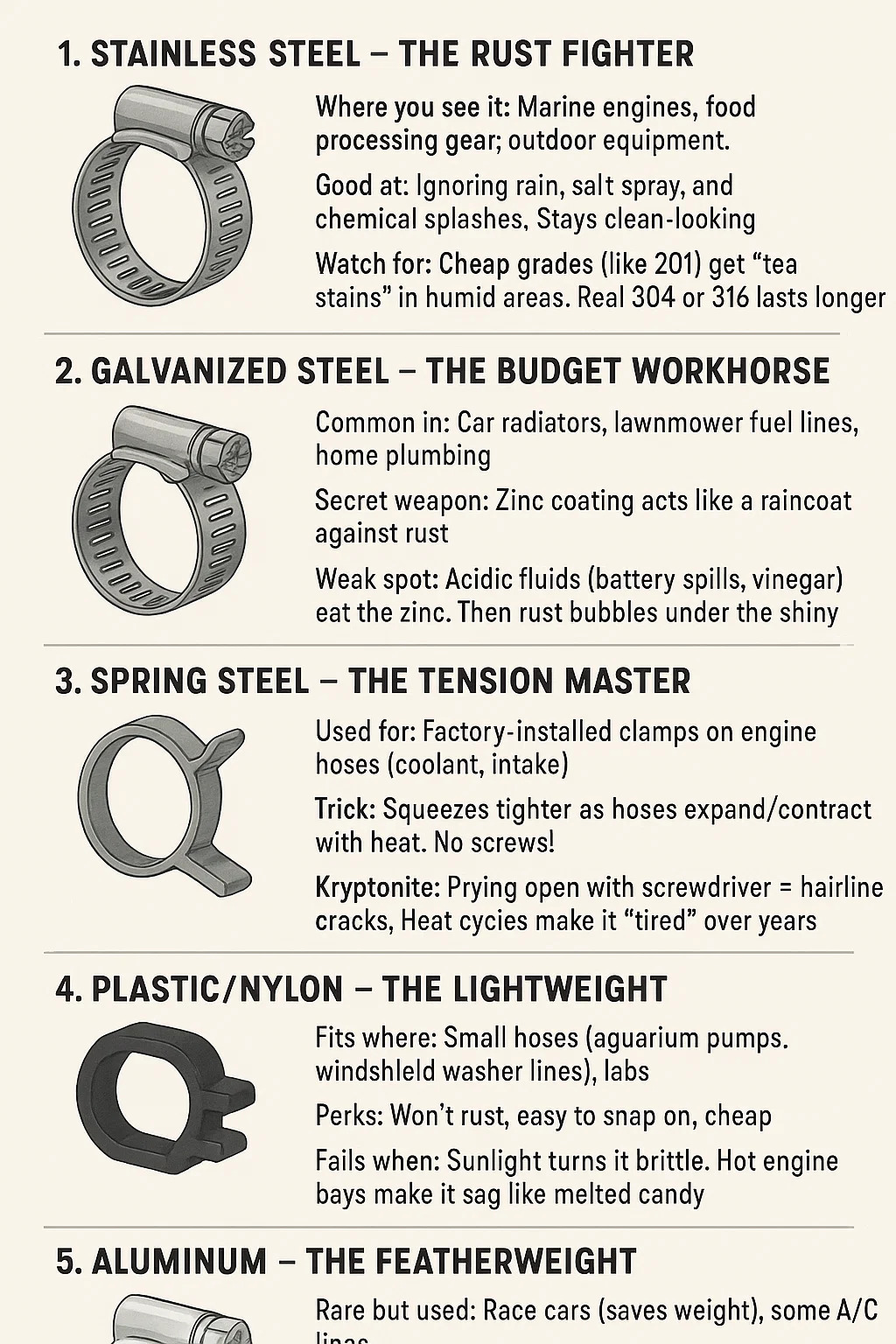

Here's a breakdown of hose clamp materials and how they hold up in the wild:

Content

1. Stainless Steel – The Rust Fighter

Where you see it: Marine engines, food processing gear, outdoor equipment.

Good at: Ignoring rain, salt spray, and chemical splashes. Stays clean-looking.

Watch for: Cheap grades (like 201) get "tea stains" in humid areas. Real 304 or 316 lasts longer.

2. Galvanized Steel – The Budget Workhorse

Common in: Car radiators, lawnmower fuel lines, home plumbing.

Secret weapon: Zinc coating acts like a raincoat against rust.

Weak spot: Acidic fluids (battery spills, vinegar) eat the zinc. Then rust bubbles under the shiny coat.

3. Spring Steel – The Tension Master

Used for: Factory-installed clamps on engine hoses (coolant, intake).

Trick: Squeezes tighter as hoses expand/contract with heat. No screws!

Kryptonite: Prying open with screwdriver = hairline cracks. Heat cycles make it "tired" over years.

4. Plastic/Nylon – The Lightweight

Fits where: Small hoses (aquarium pumps, windshield washer lines), labs.

Perks: Won’t rust, easy to snap on, cheap.

Fails when: Sunlight turns it brittle. Hot engine bays make it sag like melted candy.

5. Aluminum – The Featherweight

Rare but used: Race cars (saves weight), some A/C lines.

Pros: Light, decent corrosion resistance.

Cons: Soft metal. Overtightening crushes it. Salt turns it into chalky powder.

Material Cheat Sheet

| Material | Best For | Will Fail If… |

|---|---|---|

| Stainless | Boats, chemicals | Low-grade steel masquerading |

| Galvanized | Budget fixes | Acid touches it |

| Spring steel | Factory engines | Forced open with tools |

| Plastic | Low-pressure toys | Left in sun or heat |

| Aluminum | Weight-sensitive | Crushed or salted |

英语

英语 俄语

俄语