There really isn't a single "standard answer" to this question. It's like asking "which pair of shoes is the best?" – the answer depends on whether you're going running, hiking, or attending a wedding; the shoes you choose will be different.

To choose the "best" hose clamps, you have to consider the application. Let's categorize the scenarios and see which type reigns supreme in each field.

Content

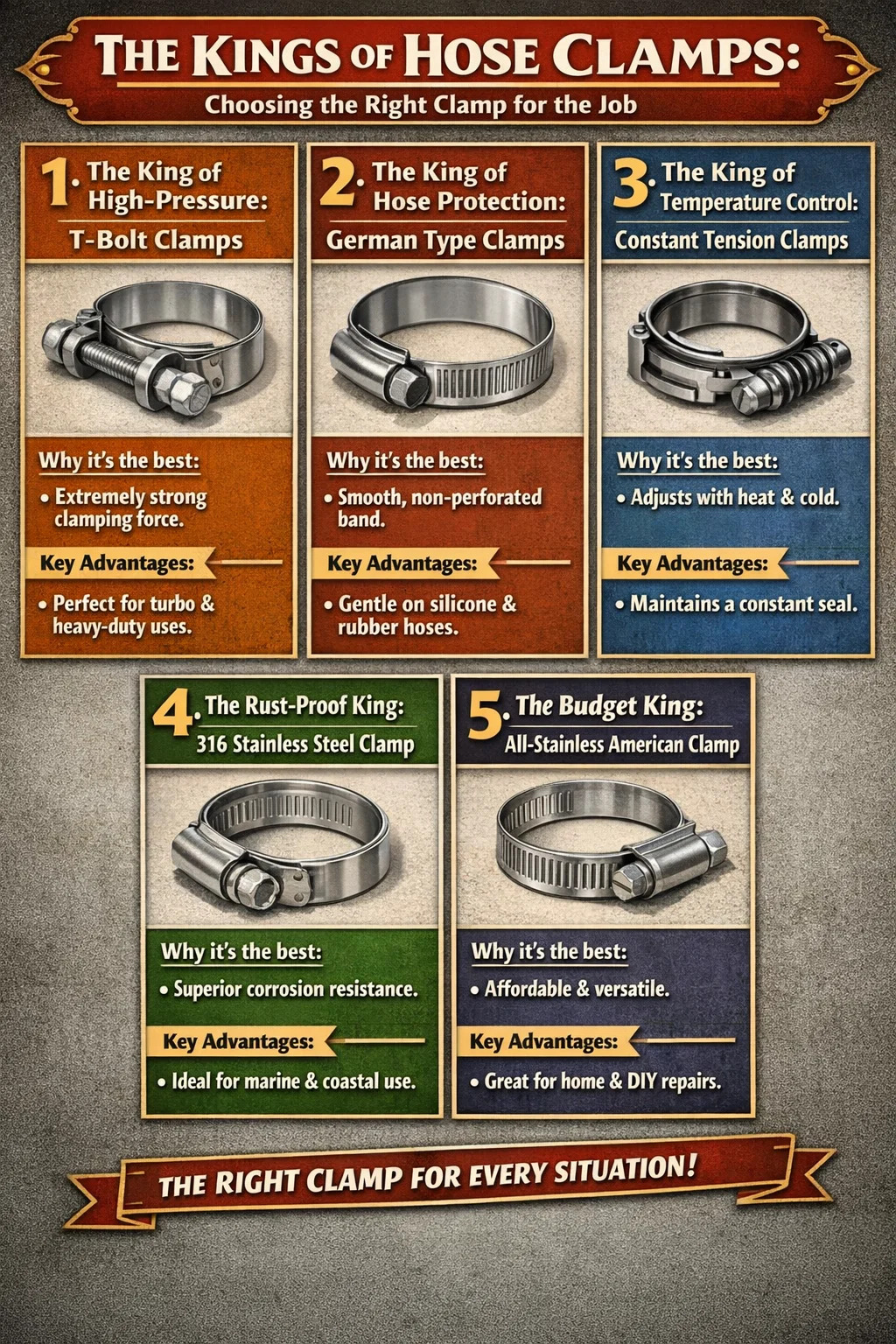

- 1 1. The King of High-Pressure, Heavy-Duty Applications: T-Bolt Clamps

- 2 2. The King of Protecting Hoses and Preventing Damage: German Type Clamps

- 3 3. The King of Handling Fluctuating Temperatures: Constant Tension Clamps

- 4 4. The rust-proof king for coastal and marine applications: 316 stainless steel hose clamp

- 5 5. The cost-effective king for home repairs: All-stainless steel American-style hose clamp

1. The King of High-Pressure, Heavy-Duty Applications: T-Bolt Clamps

If you're working on modified cars (such as turbocharger piping) or large-diameter pipes with extremely high pressure in a factory setting, ordinary clamps simply won't suffice and will be blown off in an instant.

Why it's the best: Instead of using a thin worm gear track, it uses a thick bolt and nut for tightening. The structure is extremely robust, and the clamping force is several times that of ordinary clamps.

Advantages: Once tightened, the clamp won't loosen even if the pipe bursts.

Disadvantages: Expensive, and the adjustment range is very small (usually only a few millimeters of leeway), so the size must be extremely precise when purchasing.

2. The King of Protecting Hoses and Preventing Damage: German Type Clamps

If you're using expensive silicone hoses or relatively soft rubber hoses, the biggest fear is that the clamp will cut into the hose.

Why it's the best: Its steel band doesn't have rows of perforations (a non-perforated design), the inner wall is very smooth, and the edges are rolled.

Advantages: No matter how tightly you tighten it, it won't bite into the hose like a saw. It's the gentlest on hoses and provides excellent sealing.

3. The King of Handling Fluctuating Temperatures: Constant Tension Clamps

This is the type most commonly used by car manufacturers. For example, in the radiator cooling system, the pipes expand when the car is hot and contract when it's cold.

Why it's the best: Ordinary screw clamps are rigid; when the pipe contracts, a gap appears, and the antifreeze leaks. But this type of hose clamp has a spring structure (or disc springs) inside, which allows it to "adapt" like a rubber band. Advantages: When the pipe expands, it loosens slightly; when the pipe contracts, it tightens slightly, maintaining a constant clamping force. It can be described as "fully automatic" leak prevention.

4. The rust-proof king for coastal and marine applications: 316 stainless steel hose clamp

This refers to the material, not the shape.

Why it's the best: Most hose clamps on the market are made of 304 stainless steel or even galvanized iron. However, in seawater or salt spray environments, these will rust and corrode in just a few days. Only 316-grade stainless steel is the true corrosion-resistant champion.

Advantages: It's not afraid of being submerged in seawater; it's a must-have for yachts, ships, or chemical plants.

5. The cost-effective king for home repairs: All-stainless steel American-style hose clamp

If you only have a leaky pipe at home, or a loose washing machine hose, the above options are overkill.

Why it's the best: This is the most common type, costing only a couple of dollars at hardware stores. It has a simple structure, can be tightened with just a screwdriver, and has a wide adjustment range (even a slightly larger one will work).

Note: Make sure to buy "all-stainless steel" ones. Many cheap ones have stainless steel bands but iron screws, which will rust and seize up after a couple of years.

英语

英语 俄语

俄语