Here's a practical breakdown of why camlock couplings are widely used, based on hands-on field experience:

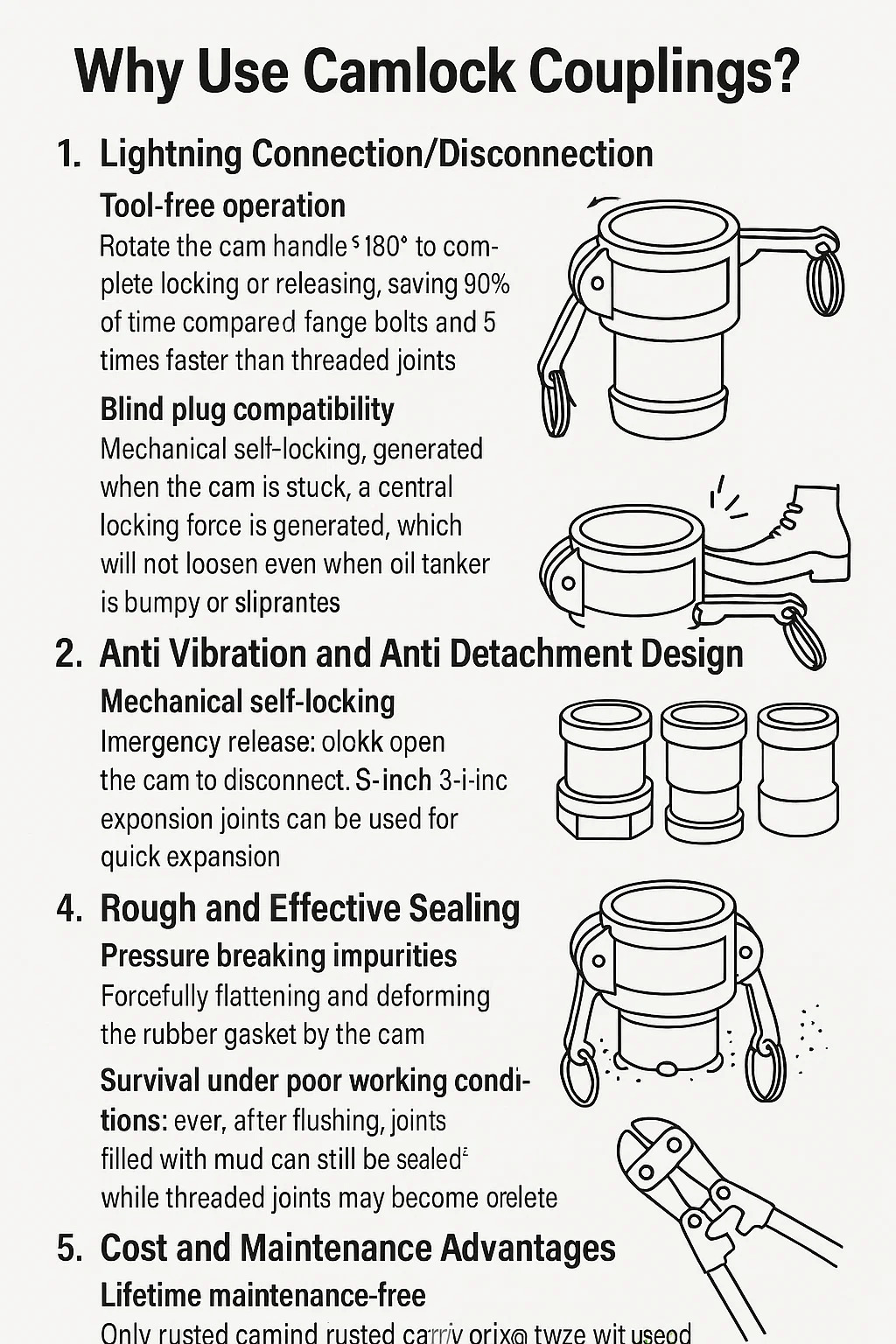

1. Lightning connection/disconnection

Tool free operation: Rotate the cam handle ≤ 180 ° to complete locking or releasing, saving 90% of time compared to flange bolts and 5 times faster than threaded joints.

Blind plug compatibility: The male and female connectors come with guide slots, allowing for quick alignment even in the dark with a tactile feel, eliminating the need for lighting during emergency repairs.

2. Anti vibration and anti detachment design

Mechanical self-locking: When the cam is stuck, a central locking force is generated, which will not loosen even when the oil tanker is bumpy or the pump vibrates.

Emergency release: In case of emergencies (such as hose tearing), simply kick open the cam to disconnect, which is safer than cutting flanges.

3. Modular universal interchange

Interface standardization: Following global standards such as ISO and DIN (such as Type A female head compatible with Type A male head), different brands of spare parts can be mixed.

Flexible Material/Size: Aluminum, stainless steel, and polypropylene interfaces of the same specification can be interchanged, and 2-inch to 3-inch expansion joints can be used for quick expansion.

4. Rough and effective sealing

Pressure breaking impurities: The rubber gasket is forcefully flattened and deformed by the cam, which can fill in scratches or sand particles attached to the surface of the joint.

Survival under poor working conditions: even after flushing, joints filled with mud can still be sealed, while threaded joints may become obsolete.

5. Cost and maintenance advantages

Lifetime maintenance free: No precision parts such as springs/gears. If the cam is rusted, pry it twice with a bolt cutter and use it as usual.

Single replacement: Only replace the male head when it is bent due to collision, and if the flange is damaged, cut and weld the entire set.

英语

英语 俄语

俄语